mesh silk screen printing

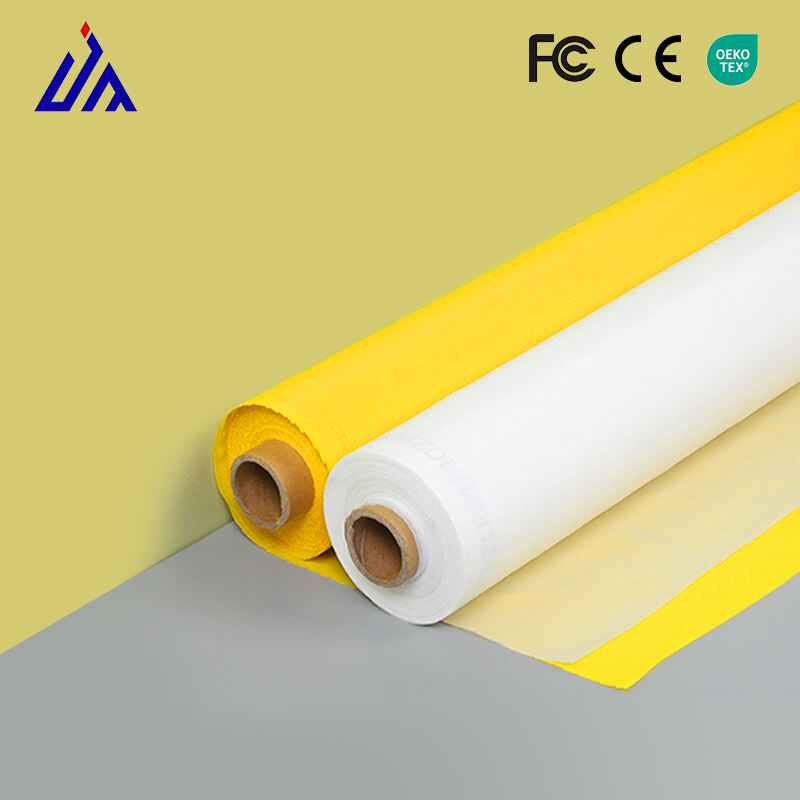

Mesh silk screen printing represents a versatile and precise printing technique that employs a finely woven mesh screen to transfer ink onto various surfaces. This sophisticated process involves stretching a mesh material, typically made from polyester or nylon, across a frame to create a printable surface. The mesh's density, measured in threads per inch, plays a crucial role in determining the print quality and detail level achievable. During the printing process, areas of the mesh are blocked off using a stencil or emulsion, creating a negative of the desired image. Ink is then pushed through the open areas of the mesh using a squeegee, depositing it onto the printing surface below. This method offers exceptional versatility, allowing for printing on diverse materials including textiles, paper, glass, metal, and plastic. The technology enables precise control over ink deposit thickness, making it ideal for applications requiring both delicate detail work and heavy coverage. Modern mesh silk screen printing systems often incorporate automated features for consistent results across large production runs, while maintaining the ability to produce unique artistic effects. The process excels in producing vibrant, durable prints with excellent color saturation and opacity, making it particularly valuable in commercial printing, textile decoration, and industrial applications.