Core Mechanics of Tunnel Dryer Efficiency

Continuous Conveyor Systems for Uninterrupted Processing

Conveyor systems are really important in tunnel dryers because they keep materials moving steadily through the process, cutting down on those annoying breaks between batches. Traditional drying methods require constant loading and unloading of materials, but continuous conveyors just keep going without stopping, which means more stuff gets dried faster. Modern conveyor tech like modular belts makes these systems much more flexible too. They can handle different sized materials and even adjust for varying moisture content without problems. When paired with automated control systems, the whole operation becomes smoother since everything loads and unloads automatically. This continuous processing capability matters a lot for manufacturers who need to maintain high output levels day after day without interruptions in their production line.

Heat Retention Technology in Enclosed Chambers

The enclosed chambers equipped with modern heat retention tech play a big role in keeping drying temps just right inside tunnel dryers. This setup cuts down on energy use while making the whole process run smoother. When heat doesn't escape so easily, we get more stable drying conditions that matter a lot for quality end products. Adding materials that store heat well inside these chambers boosts their ability to hold onto warmth, so they work efficiently even when outside temps go up and down. Thermal sensors along with feedback systems let operators watch what's happening in real time and make necessary tweaks, which keeps things running at peak performance and saves energy too. These kinds of improvements slash operating expenses and represent smart energy practices that industries need to stay competitive and environmentally responsible.

Wire Mesh Industry-Specific Drying Requirements

Drying presents some real headaches for the wire mesh industry, especially when working with metal alloys that retain lots of moisture after processing. Tunnel dryers with big heating elements work pretty well against these moisture problems. They cut down water content in metal parts substantially, which means faster production runs and better end results overall. What makes modern tunnel dryers stand out is their built-in sensors that monitor moisture as it goes through the system. This lets operators adjust drying times based on what's actually happening inside the dryer rather than guessing. Nobody wants to deal with either too much or too little drying time, and these sensors help avoid those costly mistakes. Industry studies have shown that getting the drying process right for different moisture levels really does make a difference in product quality. Components come out meeting specifications consistently while still performing reliably in their intended applications.

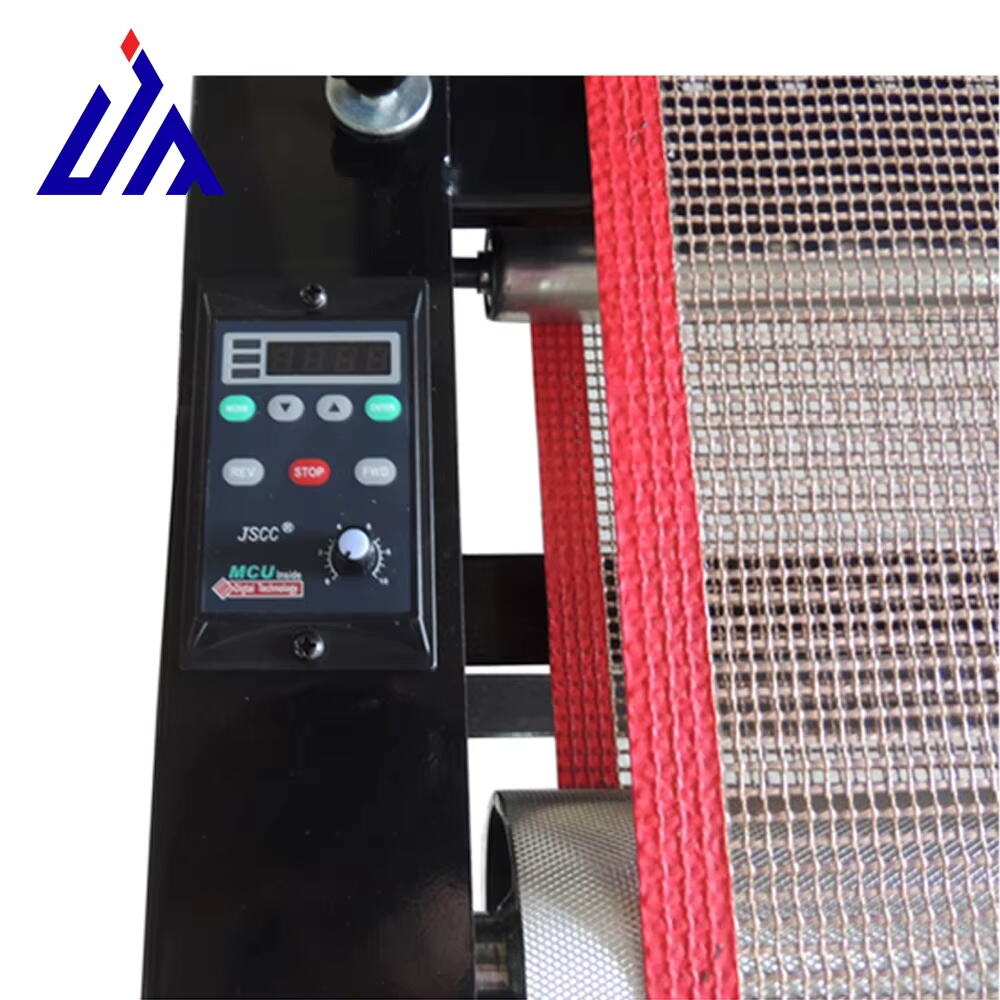

Getting things right matters a lot in industrial wire mesh production, especially when it comes to drying processes. The best tunnel dryers are built specifically for this kind of work, keeping temperatures stable while moving air through products evenly. Uniform drying throughout batches is what keeps quality high in these big operations where even small inconsistencies can cause problems down the line. Modern control panels let operators tweak settings on the fly, which makes all the difference when dealing with different types of wire mesh that have their own specific requirements. When manufacturers get serious about accurate drying techniques, they meet customer demands for quality while saving money in the long run through better efficiency.

Optimized Airflow for Enhanced Drying Performance

Strategic Ventilation Design Principles

Good ventilation design makes all the difference when it comes to getting proper airflow in tunnel dryers, which affects how fast things dry and what quality the end product ends up being. When engineers create smart ventilation setups, they actually manage airflow so there aren't these dead spots where air just sits still. The result? Faster drying times and better consistency between batches. Getting the location right for both intake vents and exhaust ports matters too because this helps spread air evenly through the whole system. Many manufacturers now use something called computational fluid dynamics modeling to see exactly how air moves inside these dryers. This lets them tweak designs before building anything physical, saving time and money while making sure everything works as intended from day one.

Humidity Control in Multi-Zone Configurations

When dealing with multi-zone tunnel dryers, getting humidity right matters a lot because different materials need their own sweet spot for proper drying. Some fabrics might want lower moisture while others require higher levels to come out just right. That's why many facilities install separate controls for each zone so they can adjust settings according to what's being processed at any given time. Most modern systems now include humidity sensors that automatically tweak conditions as needed throughout the drying cycle. These adjustments help keep quality consistent from batch to batch and cut down on damaged goods. According to recent industry data, companies that invest in good humidity management see better results in terms of product uniformity. From food processing plants to textile manufacturers, this kind of targeted approach makes all the difference when trying to hit those tight quality specifications without wasting resources.

Energy Efficiency Breakthroughs

Recapturing Waste Heat in Tunnel Systems

Getting back some of that wasted heat from tunnel dryers represents a real step forward for better energy efficiency in manufacturing plants. When companies install those heat exchanger units, they basically trap and reuse all that hot air that would otherwise just escape out the exhaust. The financial benefits are pretty obvious since this approach brings down monthly utility bills while at the same time making their operations greener. Some studies have actually shown that these recovery systems can cut energy usage by around 30 percent in certain applications. For factories running multiple shifts a day, this kind of improvement translates into thousands saved annually plus reduced carbon emissions that matter to both regulators and customers who care about environmental responsibility.

Smart Power Consumption Monitoring

The way we track power usage in tunnel dryers has changed dramatically thanks to smart monitoring systems that give operators immediate feedback on their energy consumption. These setups rely on Internet of Things tech to collect all sorts of data points about when and how much electricity gets consumed throughout the day. When businesses notice spikes in energy demand during certain hours, they can actually adjust production schedules or modify dryer settings to cut down on waste. Some plants have reported saving thousands just by shifting operations to off-peak times based on these readings. Continuous monitoring helps plant managers spot inefficiencies quickly so they can fix problems before they become expensive headaches. The bottom line? Better control over energy spending while still maintaining quality output from industrial drying processes.

Comparative Advantage Over Batch Drying

Throughput Gains in 24/7 Production Lines

When it comes to getting things done fast, tunnel dryers really shine over those old school batch drying systems. These machines keep running nonstop throughout the day and night on production floors where demand never seems to slow down. What sets them apart is their ability to handle several product runs at once while moving through the drying chamber. For food processors dealing with thousands of pounds of product daily, this setup cuts down waiting periods between batches by roughly 30% according to industry reports. While there are upfront costs involved in switching from batch to continuous processing, many manufacturers find that the boost in output justifies the investment when they need to maintain steady production levels week after week.

Quality Consistency Across Wire Mesh Batches

One major advantage that tunnel dryers bring to the table is how they maintain consistent product quality, especially important for manufacturers working with wire mesh materials. These industrial dryers basically set up the same drying conditions for every single batch going through them, cutting down on those unpredictable factors that often mess with finished product quality. When things are properly dried throughout, there's much less chance of ending up with either too wet or too dry products, both of which can ruin the whole batch. Companies that switch to tunnel drying typically see their defect rates drop dramatically along with waste reduction. The reason? Simply put, everything comes out looking pretty much the same after passing through these systems, so each production run hits those quality targets most of the time.

FAQ

How do tunnel dryers improve efficiency compared to batch dryers?

Tunnel dryers improve efficiency by enabling continuous processing without the need for loading and unloading between batches, thereby increasing throughput and reducing downtime.

What role does heat retention technology play in tunnel dryers?

Heat retention technology minimizes energy consumption by maintaining stable drying temperatures with minimal heat loss, which leads to improved operational efficiency.

Why is humidity control important in tunnel dryers?

Humidity control is crucial for tailoring drying environments to specific materials, ensuring consistent product quality and minimizing the risk of damage.

How does smart power consumption monitoring benefit tunnel dryer operations?

Smart power consumption monitoring provides real-time energy usage insights, allowing businesses to optimize operations and reduce costs effectively.