Essential Tools for Professional Screen Printing Success

In the dynamic world of screen printing, having the right equipment can make all the difference between mediocre results and professional-quality prints. At the heart of this craft lies an indispensable tool - the screen stretcher. This precision instrument ensures your mesh is tensioned perfectly every time, leading to sharper prints, consistent results, and improved productivity in your printing operations.

Whether you're expanding your printing business or upgrading your existing equipment, understanding the nuances of screen stretchers is crucial for making an informed investment. These sophisticated devices have evolved significantly over the years, incorporating advanced features that enhance both efficiency and precision in the screen preparation process.

Understanding Screen Stretcher Technology

Mechanical vs. Pneumatic Systems

Screen stretchers come in two primary variants: mechanical and pneumatic systems. Mechanical screen stretchers utilize manual tension adjustment through clamps and handles, offering precise control over the stretching process. These systems are particularly popular in smaller workshops where consistent, hands-on control is preferred.

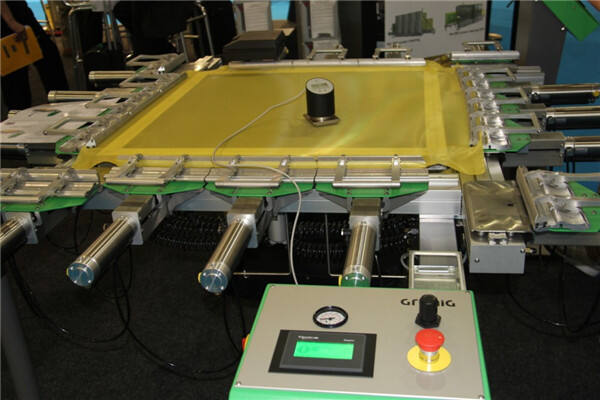

Pneumatic screen stretchers, on the other hand, employ compressed air to achieve and maintain tension. These advanced systems provide uniform tension across all sides simultaneously, reducing the risk of uneven stretching. The automated nature of pneumatic screen stretchers makes them ideal for high-volume production environments where efficiency and consistency are paramount.

Modern Features and Innovations

Contemporary screen stretchers incorporate various innovative features that enhance their functionality. Digital tension meters, preset tension memory, and automatic tension maintenance systems ensure precise and repeatable results. Some advanced models even include touch-screen interfaces that allow operators to save and recall specific tension settings for different mesh types.

The latest generation of screen stretchers also features improved clamp designs that minimize mesh damage while providing superior grip strength. These developments have significantly reduced the learning curve for operators while improving the overall quality of stretched screens.

Selecting the Right Size and Configuration

Maximum Frame Capacity

When choosing a screen stretcher, the maximum frame capacity is a crucial consideration. Your selection should accommodate not only your current frame sizes but also potential future needs. Professional screen stretchers typically handle frame sizes ranging from small format (20x24 inches) to large format (40x60 inches or larger).

Consider your production requirements and available workspace when determining the optimal size. While larger screen stretchers offer more versatility, they also require more floor space and may represent a higher initial investment. Some manufacturers offer modular systems that can be expanded as your business grows.

Stretching Configuration Options

Different screen stretchers offer varying configuration options for mesh tensioning. Some models provide two-way stretching (opposing sides), while others feature four-way stretching capabilities. Four-way stretching systems generally achieve more uniform tension across the entire mesh surface, resulting in better print quality.

Advanced models may include corner clamping systems that help prevent mesh slippage and ensure even tension distribution. The ability to adjust individual clamp positions and tensions independently allows for fine-tuning of the stretching process based on specific mesh characteristics.

Material Quality and Construction

Frame Construction and Durability

The construction quality of a screen stretcher directly impacts its longevity and performance. Look for units built with heavy-duty materials like steel or aluminum alloys that can withstand repeated use while maintaining structural integrity. The frame should be rigid enough to prevent flexing during the stretching process, as any movement can affect tension uniformity.

Surface treatments and coatings play a vital role in protecting the screen stretcher from corrosion and wear. Premium models often feature anodized or powder-coated surfaces that resist chemical exposure and physical damage, ensuring years of reliable service.

Clamp System Quality

The clamp system is perhaps the most critical component of any screen stretcher. High-quality clamps should provide consistent grip strength without damaging the mesh material. Look for models with replaceable grip surfaces and easy adjustment mechanisms that maintain their settings over time.

Superior clamp systems often incorporate specialized materials like hardened steel or precision-machined components that ensure reliable performance. The ability to quickly release and reset clamps can significantly impact productivity, especially in high-volume operations.

Maintenance and Support Considerations

Regular Maintenance Requirements

A well-maintained screen stretcher will provide years of reliable service. Regular maintenance typically includes cleaning the clamps, lubricating moving parts, and checking pneumatic system components when applicable. Choose a model with easily accessible maintenance points and straightforward service procedures.

Consider the availability of replacement parts and the manufacturer's support network when selecting a screen stretcher. Some manufacturers offer comprehensive maintenance packages and training programs to ensure optimal equipment performance.

Warranty and Technical Support

The warranty coverage and available technical support can significantly impact the total cost of ownership. Leading manufacturers typically offer extended warranties on major components and provide responsive technical support. This support can be crucial when troubleshooting issues or optimizing stretching parameters for different mesh types.

Look for manufacturers that maintain detailed documentation, offer online support resources, and provide direct access to technical experts who can assist with setup and ongoing operation.

Frequently Asked Questions

How often should I calibrate my screen stretcher?

For optimal performance, calibrate your screen stretcher at least every six months or after stretching approximately 500 screens. However, if you notice any inconsistencies in tension or print quality, immediate calibration may be necessary. Regular calibration ensures consistent tension across all frames and maintains print quality standards.

What tension levels are recommended for different mesh counts?

Tension requirements vary based on mesh count and material. Generally, lower mesh counts (60-110) require 15-20 N/cm, medium mesh counts (120-200) need 20-25 N/cm, and high mesh counts (230+) perform best at 25-30 N/cm. Always consult your mesh manufacturer's specifications for optimal tension ranges.

Can I stretch multiple screens simultaneously?

Most professional screen stretchers can accommodate multiple frames simultaneously, depending on the model's size and configuration. However, it's essential to ensure all frames are the same size and require similar tension settings for optimal results. When stretching multiple screens, verify that the stretcher's capacity can handle the combined load without compromising tension uniformity.