What Are the Advantages of Using Automatic vs. Manual Screen Printing Machines?

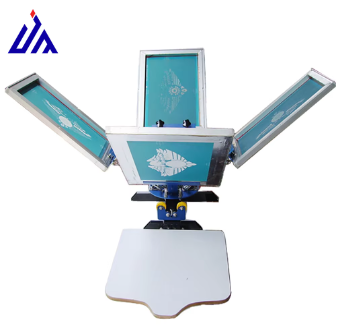

Choosing between an automatic and a manual screen printing machine depends on production needs, budget, and the type of projects you handle. A manual screen printing machine relies on human operation for tasks like aligning screens, applying ink, and moving materials, while an automatic screen printing machine uses motors, sensors, and programmable settings to handle these steps automatically. Both have their place in the industry, but their advantages differ significantly in terms of speed, consistency, labor, and scalability. This guide compares the advantages of automatic vs. manual screen printing machines, helping you decide which best fits your workflow.

Speed and Production Volume

One of the most significant differences between automatic and manual screen printing machines is their speed and ability to handle large production volumes.

- Automatic Screen Printing Machine: Designed for high-volume production, an automatic screen printing machine can print hundreds to thousands of items per hour. It uses conveyor systems to move materials (like t-shirts or posters) through the printing process continuously, with multiple stations applying different colors simultaneously. For example, a 6-color automatic machine can print a full design in one pass, rather than requiring separate steps for each color. This speed makes it ideal for large orders, such as corporate apparel, event merchandise, or bulk packaging.

- Manual Screen Printing Machine: A manual screen printing machine is slower, typically handling 20–50 items per hour for multi-color designs. Each print requires manual effort: the operator aligns the material, lowers the screen, applies ink with a squeegee, lifts the screen, and moves the item to the drying area. This pace works well for small batches, custom orders, or hobby projects but becomes inefficient for large volumes.

The automatic screen printing machine’s speed advantage is clear for businesses needing to meet high demand, while manual machines suit low-volume or custom work.

Consistency and Print Quality

Consistency in print quality—such as even ink coverage, precise alignment, and uniform color—is critical for professional results.

- Automatic Screen Printing Machine: An automatic screen printing machine delivers superior consistency because it eliminates human error. Programmable settings control squeegee pressure, speed, and ink application, ensuring every print matches the first. Sensors and registration systems keep multi-color designs perfectly aligned, reducing misprints. The machine also maintains steady ink flow and pressure, preventing streaks or uneven coverage that can occur with manual operation. This reliability is essential for brands that need consistent branding across all products.

- Manual Screen Printing Machine: While skilled operators can achieve high quality with a manual screen printing machine, consistency is harder to maintain. Factors like varying squeegee pressure, slight misalignment, or fatigue can lead to differences between prints. Multi-color designs require careful manual registration, which increases the risk of misalignment, especially over long production runs. Manual machines work well for simple designs or one-of-a-kind prints but struggle with the precision needed for large batches of detailed work.

For businesses prioritizing uniform, professional results, an automatic screen printing machine offers a clear advantage.

Labor Requirements and Efficiency

Labor costs and efficiency play a major role in choosing between automatic and manual screen printing machines.

- Automatic Screen Printing Machine: An automatic screen printing machine reduces labor needs significantly. While setup requires skilled operators to program settings, align screens, and load materials, the printing process itself runs with minimal supervision. A single operator can monitor an automatic machine handling multiple stations, freeing up staff for other tasks like prepping materials or quality checks. This efficiency lowers labor costs per item, especially for large orders, making it cost-effective for high-volume production.

- Manual Screen Printing Machine: A manual screen printing machine requires constant hands-on work. Each print needs an operator to align the material, apply ink, and move the item to drying. For multi-color jobs, operators must change screens and re-register the design, increasing labor time. This makes manual machines more labor-intensive, with higher costs per item for large orders. However, they require less training to operate, making them accessible for beginners or small teams.

Automatic machines save time and labor for large-scale operations, while manual machines are more suitable for small teams or low-volume work.

Scalability and Versatility

The ability to scale production and handle diverse projects is another key difference between the two types of screen printing machines.

- Automatic Screen Printing Machine: An automatic screen printing machine is highly scalable, making it easy to increase production as demand grows. Many models allow adding more printing stations (for extra colors) or upgrading components (like faster dryers) to boost output. They handle a range of materials, including fabrics, plastics, and metals, with adjustable settings to match different surfaces. This versatility makes them suitable for businesses expanding into new product lines, such as moving from t-shirts to bags or signage.

- Manual Screen Printing Machine: Manual screen printing machines are less scalable, as their speed is limited by operator capacity. Upgrading to handle larger volumes typically requires buying additional manual machines or hiring more operators, which can be costly. While they work with various materials, adjusting settings for different surfaces (like thick fabric vs. thin paper) takes more time and effort than with an automatic machine. Manual machines are best for businesses with steady, low-volume needs or those focusing on custom, niche products.

Automatic machines support growth and diversification, while manual machines are better for stable, small-scale operations.

Cost Considerations

Initial investment and long-term costs differ between automatic and manual screen printing machines.

- Automatic Screen Printing Machine: An automatic screen printing machine has a higher upfront cost, ranging from thousands to tens of thousands of dollars, depending on the number of stations and features. However, it offers lower long-term costs for high-volume production. Reduced labor needs, faster output, and fewer misprints lower the cost per item, making the investment worthwhile for businesses with consistent large orders.

- Manual Screen Printing Machine: A manual screen printing machine is much cheaper initially, with basic models costing a few hundred to a few thousand dollars. This makes it accessible for startups, hobbyists, or small businesses with limited budgets. However, long-term costs can be higher for large orders due to increased labor and slower production. Manual machines also have higher waste rates from misprints, adding to costs over time.

The automatic screen printing machine is a better investment for high-volume operations, while manual machines are more cost-effective for small-scale use.

Ease of Use and Training

The learning curve and training required to operate each machine vary significantly.

- Automatic Screen Printing Machine: Operating an automatic screen printing machine requires more training. Operators need to understand how to program settings, calibrate sensors, troubleshoot mechanical issues, and maintain the machine’s complex components (like conveyor belts and curing systems). However, once set up, the machine runs automatically, reducing the need for constant adjustment. Skilled operators can maximize efficiency by optimizing settings for different materials and designs.

- Manual Screen Printing Machine: A manual screen printing machine is easier to learn and operate. Basic models have simple controls—levers to lower screens, manual squeegees, and basic alignment tools—making them accessible to beginners. Training focuses on proper squeegee technique, registration, and ink handling, which can be mastered in a short time. This ease of use makes manual machines popular for workshops, schools, or small businesses with rotating staff.

Manual machines are better for teams with limited experience, while automatic machines require skilled operators but offer greater efficiency.

FAQ

Can an automatic screen printing machine handle small orders?

Yes, but it may be inefficient. Automatic machines require setup time, so small orders may not justify the effort. Manual machines are more cost-effective for small batches.

Is a manual screen printing machine better for detailed designs?

Not necessarily. While skilled operators can print details manually, automatic machines with high-tension screens and precise registration systems consistently produce sharper, more detailed prints.

How much space does an automatic screen printing machine take?

Automatic machines are larger, requiring 10–30 square meters (100–300 square feet) depending on the number of stations and conveyor length. Manual machines are compact, fitting in small workshops.

Do automatic screen printing machines need more maintenance?

Yes, automatic machines have more moving parts (motors, conveyors, sensors) that require regular lubrication, cleaning, and inspection. Manual machines have fewer components, so maintenance is simpler.

Can a manual machine be upgraded to automatic?

Some manual machines can be retrofitted with automatic components (like motorized squeegees), but full automation is usually more cost-effective with a dedicated automatic machine.