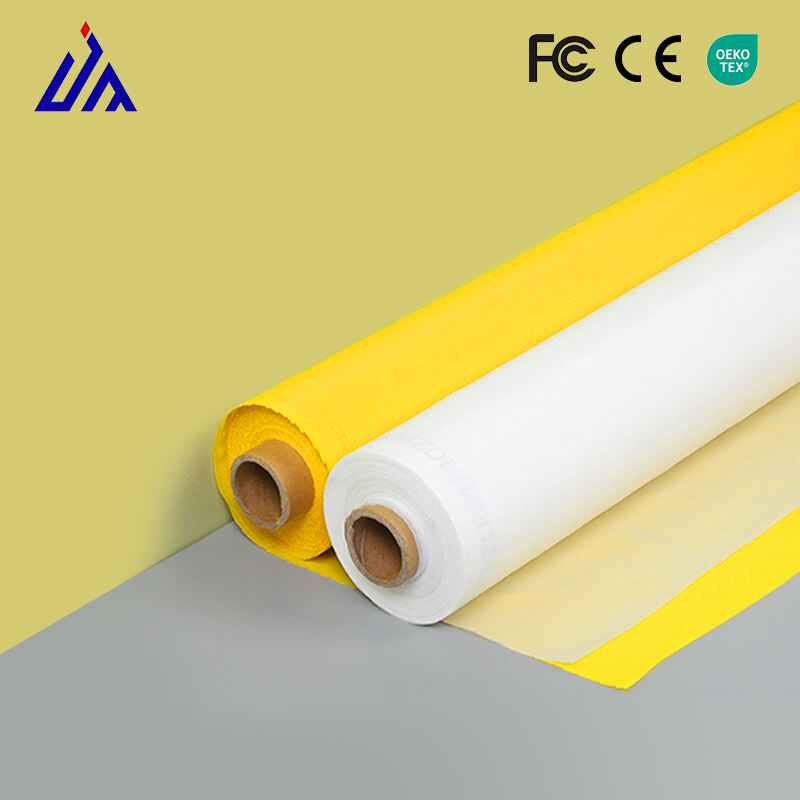

mesh size for screen printing

Mesh size in screen printing refers to the number of threads per inch in a screen printing mesh, playing a crucial role in determining print quality and detail reproduction. This measurement directly affects the amount of ink that passes through the screen and onto the substrate. Typically ranging from 60 to 420 threads per inch, different mesh sizes serve various printing requirements. Lower mesh counts like 60-110 are ideal for printing thicker deposits of ink, making them perfect for printing white ink on dark fabrics or creating special effects like glitter prints. Medium mesh counts between 110-200 are versatile and commonly used for general purpose printing, offering good ink deposit while maintaining decent detail. Higher mesh counts of 200-420 are designed for fine detail printing, halftones, and process color work, especially when working with thin inks or requiring precise detail reproduction. The thread diameter and weave pattern also influence the printing characteristics, affecting both ink flow and image resolution. Understanding mesh size selection is fundamental for achieving optimal print results, as it impacts not only the final print quality but also the production efficiency and ink consumption.