silk screen printing frame

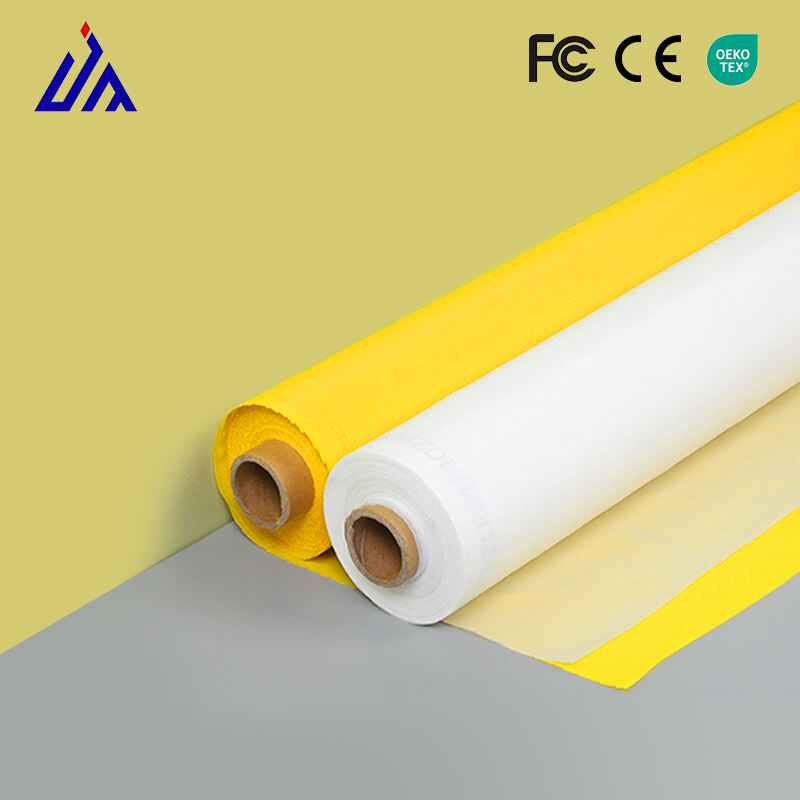

A silk screen printing frame serves as the fundamental foundation for screen printing processes, combining durability and precision in a versatile structure. This essential equipment consists of a rigid frame, typically manufactured from aluminum or wooden materials, supporting a finely woven mesh stretched tightly across its surface. The frame maintains consistent tension in the mesh, ensuring accurate print reproduction and long-lasting performance. Modern silk screen printing frames feature precise engineering that allows for optimal ink transfer and pattern definition, making them ideal for various printing applications. The mesh, traditionally made from silk but now commonly utilizing synthetic materials like polyester, is carefully calibrated to different thread counts suitable for diverse printing requirements. These frames accommodate different sizes and configurations, enabling printing on various substrates including textiles, paper, plastics, and metal surfaces. The construction of these frames incorporates tension control systems that maintain mesh stability during repeated use, preventing sagging or distortion that could compromise print quality. Advanced frames may include registration markers and alignment systems that facilitate precise positioning and multi-color printing processes. The design also considers practical aspects such as ease of cleaning, storage, and compatibility with different printing equipment and techniques.