Understanding Screen Printing Frame Technologies in Modern Printing Systems

The world of industrial printing has evolved significantly over the years, with screen printing frames playing a pivotal role in both flatbed and rotary printing systems. These essential components serve as the foundation for achieving precise, high-quality prints across various materials and applications. The fundamental differences between frames used in flatbed and rotary printing machines reflect not only their mechanical requirements but also their specific operational advantages.

Screen printing frames form the backbone of the printing process, providing the necessary tension and stability for the mesh that carries the printing design. Whether used in flatbed or rotary systems, these frames must maintain consistent tension while withstanding the rigors of commercial printing operations. Understanding their distinct characteristics helps manufacturers optimize their printing processes and achieve superior results.

Structural Components of Flatbed Printing Frames

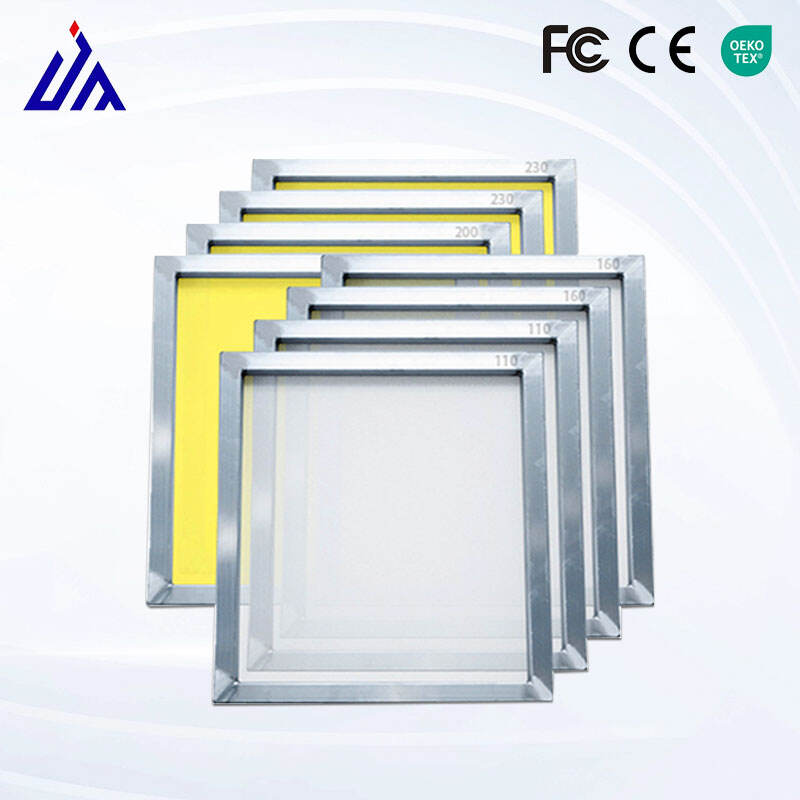

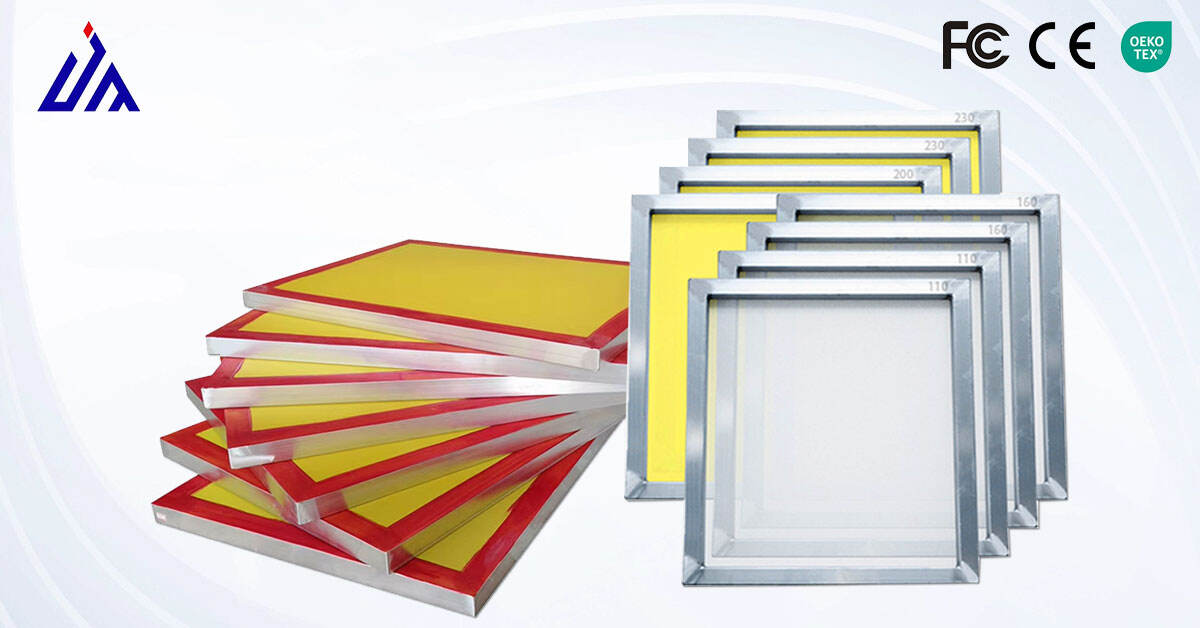

Frame Material and Construction

Flatbed screen printing frames typically feature robust aluminum or steel construction, designed to maintain perfect planarity across the entire printing surface. The material choice significantly influences the frame's performance, with aluminum offering lightweight handling and corrosion resistance, while steel provides maximum rigidity for high-tension applications.

The corners of flatbed frames are precision-welded or mechanically joined to ensure perfect square alignment. This structural integrity is crucial for maintaining consistent registration and preventing distortion during the printing process. Modern flatbed frames often incorporate reinforcement ribs or honeycomb structures to enhance stability while minimizing weight.

Tension Control Systems

Flatbed screen printing frames employ various tension control mechanisms to maintain optimal mesh tension. Pneumatic and mechanical stretching systems allow operators to achieve uniform tension across the entire screen surface. The frame's design must accommodate these tension adjustments while preventing warping or deformation.

Advanced flatbed frames feature integrated tension monitoring systems that help maintain consistent print quality throughout production runs. These systems often include calibrated tension meters and adjustable corner clamps that enable precise tension control and easy mesh replacement when necessary.

Rotary Printing Frame Characteristics

Cylindrical Design Elements

Rotary screen printing frames feature a distinctive cylindrical construction that enables continuous printing operations. The seamless design of these frames requires specialized manufacturing processes to ensure perfect roundness and balance during high-speed rotation. The frame's circumference must maintain exact specifications to synchronize with the printing machine's registration system.

Material selection for rotary frames emphasizes lightweight yet rigid compositions, often utilizing nickel-plated steel or specialized alloys. The cylindrical structure must resist deformation while maintaining perfect concentricity throughout the printing process. End rings and support systems are precisely engineered to facilitate smooth rotation and proper mesh attachment.

Dynamic Balance Requirements

Unlike flatbed frames, rotary screen printing frames must maintain perfect dynamic balance during operation. This requires precise engineering of the frame's mass distribution and careful consideration of end-ring design. Manufacturers employ sophisticated balancing techniques to ensure smooth operation at high production speeds.

The frame's design incorporates features that facilitate quick changeovers while maintaining registration accuracy. Special attention is given to the end-ring interface with the printing machine's drive system, ensuring consistent rotation and preventing vibration during operation.

Performance Considerations and Applications

Production Speed Capabilities

Screen printing frames for flatbed systems typically support intermittent printing operations, with production speeds determined by the stroke rate and drying requirements. The frame design focuses on stability during the squeegee stroke and quick recovery between impressions. Modern flatbed frames incorporate features that minimize setup time and facilitate rapid screen changes.

Rotary printing frames, conversely, enable continuous high-speed production with minimal interruption. The cylindrical frame design supports seamless printing operations, often achieving production speeds several times faster than flatbed systems. This advantage makes rotary frames particularly suitable for high-volume applications in textile and wallcovering production.

Application-Specific Adaptations

Flatbed screen printing frames excel in applications requiring thick ink deposits or precise detail reproduction. The frame design allows for various mesh tensions and squeegee pressures, making them ideal for specialty printing on rigid substrates. Industries such as electronics and graphic arts often prefer flatbed frames for their versatility and precision.

Rotary frames find their niche in continuous web printing applications, particularly in textile and packaging industries. The frame design accommodates specialized features for specific applications, such as integrated ink feed systems or temperature control mechanisms. These adaptations enhance production efficiency while maintaining print quality standards.

Maintenance and Longevity Factors

Cleaning and Storage Protocols

Proper maintenance of screen printing frames significantly impacts their operational life and performance. Flatbed frames require regular cleaning and inspection of corner joints and tension mechanisms. Storage systems must support the frame without introducing stress points that could affect alignment or mesh tension.

Rotary frames demand careful handling during cleaning to prevent damage to the cylindrical surface or end rings. Specialized storage solutions protect the frames from physical damage while maintaining their precise roundness. Regular inspection of bearing surfaces and drive mechanisms ensures consistent performance.

Wear Pattern Management

Understanding wear patterns helps extend frame life and maintain print quality. Flatbed frames may experience stress concentration at corner joints and tension adjustment points. Regular monitoring and preventive maintenance address these areas before they affect production quality.

Rotary frames typically show wear in end-ring areas and at drive mechanism interface points. Implementing rotation schedules and conducting regular balance checks helps distribute wear evenly and maintain optimal performance. Proper documentation of maintenance activities supports predictive maintenance programs.

Frequently Asked Questions

What factors determine the choice between flatbed and rotary screen printing frames?

The decision depends on several key factors including production volume requirements, substrate type, print design complexity, and required ink deposit thickness. Flatbed frames offer versatility and precision for shorter runs and specialized applications, while rotary frames excel in high-speed continuous production environments.

How often should screen printing frames be replaced or serviced?

Maintenance intervals vary based on usage patterns and operating conditions. Generally, frames should undergo thorough inspection every 3-6 months, with service procedures determined by wear indicators and performance metrics. Professional evaluation helps establish appropriate maintenance schedules for specific applications.

What are the latest innovations in screen printing frame technology?

Recent advances include smart tension monitoring systems, lightweight composite materials for improved stability, and automated cleaning systems. New frame designs incorporate features for quick changeover and enhanced registration accuracy, while materials science developments continue to improve frame durability and performance.