Essential Components of Professional Screen Printing Frame Selection

The foundation of successful screen printing lies in selecting the appropriate frame for your specific project needs. A screen printing frame serves as the backbone of the printing process, directly influencing print quality, production efficiency, and overall project success. Understanding the vital role these frames play helps ensure optimal results for both small-scale artistic endeavors and large commercial productions.

When embarking on a screen printing project, the frame choice impacts everything from image resolution to production speed and durability. Making an informed decision requires careful consideration of multiple factors, from material composition to size specifications. Let's explore the critical elements that should guide your frame selection process.

Frame Materials and Their Properties

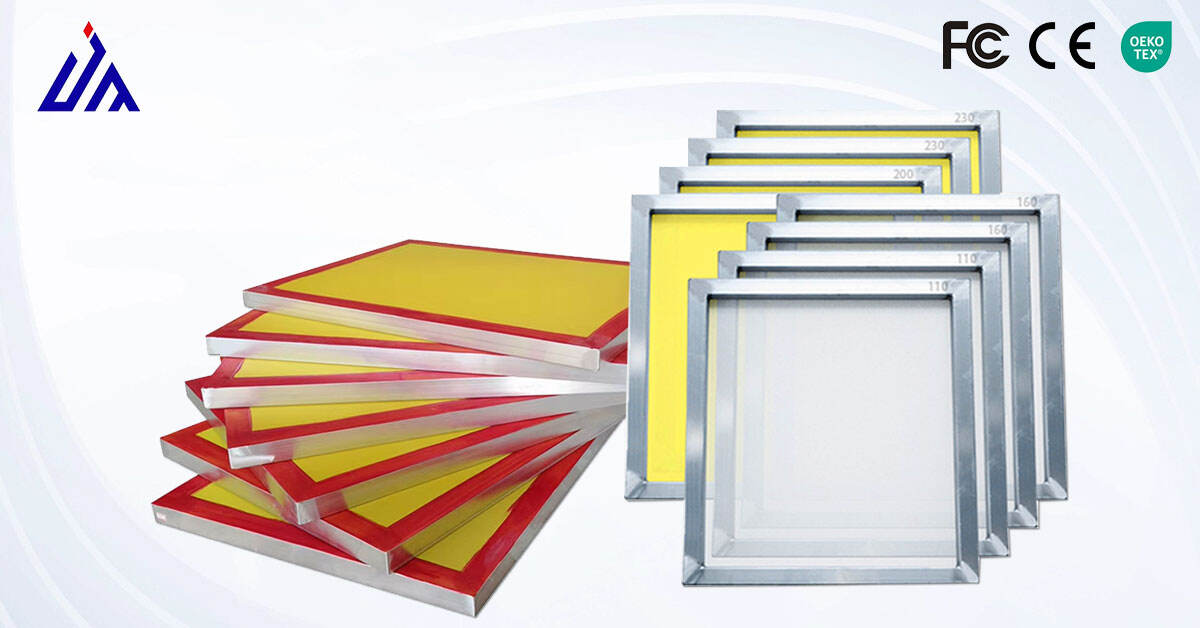

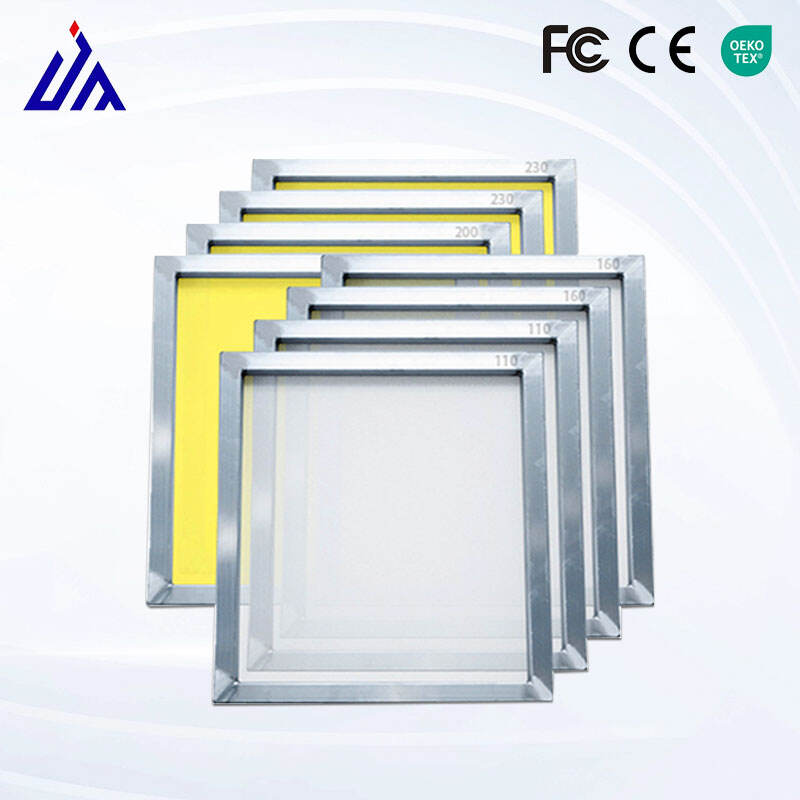

Aluminum Frame Characteristics

Aluminum frames have become increasingly popular in modern screen printing operations. These lightweight yet durable frames offer excellent stability and resist warping under tension. The corrosion-resistant nature of aluminum makes these frames ideal for environments with varying humidity levels. Professional printers often prefer aluminum frames for their exceptional strength-to-weight ratio and ability to maintain consistent tension over extended periods.

The thermal properties of aluminum frames also prove advantageous during the printing process. They help dissipate heat effectively, reducing the risk of screen distortion during high-volume printing runs. Additionally, aluminum frames typically feature precise corner construction, ensuring maintained registration throughout the production cycle.

Wooden Frame Applications

Traditional wooden screen printing frames continue to hold their place in certain applications, particularly in artistic and educational settings. These frames offer natural flexibility and are often more cost-effective for beginners or small-scale operations. Wood frames excel in applications where frequent screen changes aren't necessary, and their natural dampening properties can be beneficial for certain printing techniques.

However, wooden frames require more maintenance and careful storage to prevent warping and degradation. They perform best in controlled environments where temperature and humidity remain stable. The organic nature of wood means these frames may need replacement more frequently than their metal counterparts.

Size and Tension Considerations

Determining Optimal Frame Dimensions

The dimensions of your screen printing frame must accommodate both your artwork size and the printing substrate requirements. Professional guidelines suggest maintaining at least 2-3 inches of clearance between the image area and frame edge to ensure proper tension distribution. Larger frames provide more stability during printing but require more storage space and may be more challenging to handle.

Consider the relationship between frame size and mesh tension capabilities. Larger frames typically require higher tension thresholds to maintain print quality. The frame's profile depth also plays a crucial role in tension maintenance, with deeper profiles generally offering better stability for high-tension applications.

Tension Control and Maintenance

Proper tension control represents a critical aspect of screen printing frame performance. Modern retensionable frames offer advantages in maintaining consistent tension levels throughout multiple print runs. The ability to adjust tension as needed helps extend screen life and ensures consistent print quality across production runs.

Understanding tension measurement and monitoring techniques becomes essential for maintaining optimal printing conditions. Regular tension checks and adjustments help prevent common issues like image distortion and poor registration. Professional printers often implement systematic tension monitoring protocols to maintain quality standards.

Durability and Longevity Factors

Construction Quality Assessment

The construction quality of a screen printing frame directly impacts its longevity and performance reliability. Professional-grade frames feature reinforced corners and precise welding or joinery techniques that prevent weakness at stress points. Evaluating construction quality involves examining corner joints, surface finishing, and overall frame rigidity.

High-quality frames often incorporate additional features like reinforced mounting points and specialized coating treatments that enhance durability. These features contribute to extended frame life and improved resistance to chemical exposure from inks and cleaning solutions.

Maintenance Requirements

Different frame types require varying levels of maintenance to ensure optimal performance and longevity. Establishing a regular maintenance schedule helps identify potential issues before they affect print quality. This includes cleaning protocols, tension checks, and periodic inspections for signs of wear or damage.

Proper storage conditions play a crucial role in frame longevity. Temperature-controlled environments and appropriate storage systems help prevent frame warping and maintain consistent performance characteristics. Investment in proper maintenance supplies and storage solutions proves cost-effective in the long run.

Cost Considerations and Return on Investment

Initial Investment Analysis

While initial frame costs vary significantly, considering long-term value proves more important than focusing solely on purchase price. Professional-grade frames typically command higher prices but offer extended service life and superior performance characteristics. Analyzing cost per print run helps determine the true value of different frame options.

Consider factors like production volume, required print quality, and anticipated project longevity when evaluating frame investments. Higher-quality frames often provide better value through reduced replacement needs and improved print consistency.

Long-term Economic Impact

The economic impact of frame selection extends beyond initial purchase costs. Factors like maintenance requirements, replacement frequency, and production efficiency all contribute to the total cost of ownership. Professional operations benefit from tracking these metrics to optimize frame selection for different project types.

Consider how frame choice affects other production costs, including labor efficiency and material waste. Superior frames often reduce setup time and minimize registration issues, leading to improved overall productivity.

Frequently Asked Questions

How often should screen printing frames be replaced?

The replacement frequency for screen printing frames depends on various factors including usage intensity, maintenance practices, and storage conditions. Generally, aluminum frames can last several years with proper care, while wooden frames may require replacement every 1-2 years. Regular inspection and maintenance can significantly extend frame life.

What's the ideal tension range for screen printing frames?

Optimal tension ranges vary based on mesh count and application requirements. Generally, mesh tensions between 18-25 N/cm provide good results for most applications. Higher mesh counts typically require higher tension levels, while lower mesh counts can perform well at lower tensions.

Can different frame materials be used interchangeably for the same project?

While different frame materials can technically be used for similar projects, each material type offers distinct advantages and limitations. Professional printers typically select specific frame materials based on project requirements, production volume, and quality standards rather than using them interchangeably.