Screen printing professionals often face a critical decision when setting up their workshops: choosing between a screen stretcher and frame clamps for mesh tensioning. This fundamental choice impacts print quality, production efficiency, and long-term operational costs. Understanding the differences between these two essential tools can transform your screen printing operations from amateur to professional grade. Both options serve the primary function of creating properly tensioned screens, but they accomplish this goal through distinctly different mechanisms and offer varying levels of precision, speed, and consistency.

Understanding Screen Stretching Fundamentals

The Science Behind Proper Mesh Tension

Proper mesh tension forms the foundation of successful screen printing operations. When mesh lacks adequate tension, ink deposits become uneven, registration suffers, and print quality deteriorates significantly. Professional screen printers understand that consistent tension across the entire mesh surface ensures sharp image reproduction and reliable ink transfer. The tension measurement, typically expressed in Newtons per centimeter, must remain uniform to prevent distortion during the printing process.

Modern screen printing demands increasingly precise tension control as substrate materials become more diverse and print requirements more stringent. Inadequate tension creates problems ranging from poor ink release to premature screen failure. The relationship between mesh count, thread diameter, and required tension creates a complex equation that professional tools must address consistently. Understanding these fundamentals helps determine whether manual frame clamps or automated screen stretching equipment better serves specific production needs.

Tension Consistency and Print Quality Correlation

Research demonstrates a direct correlation between tension consistency and final print quality across various screen printing applications. Screens with uniform tension produce sharper halftones, cleaner line work, and more consistent color reproduction throughout production runs. Tension variations as small as five percent can create visible quality differences in demanding applications such as electronics printing or high-end graphics work.

Professional screen printers monitor tension levels using specialized gauges, but the initial stretching process largely determines long-term consistency. Screens stretched with inadequate equipment often develop tension variations that compound over time, leading to premature replacement and increased material costs. The investment in proper stretching equipment typically pays for itself through reduced screen replacement costs and improved print consistency across extended production runs.

Screen Stretcher Technology and Capabilities

Automated Stretching Mechanisms

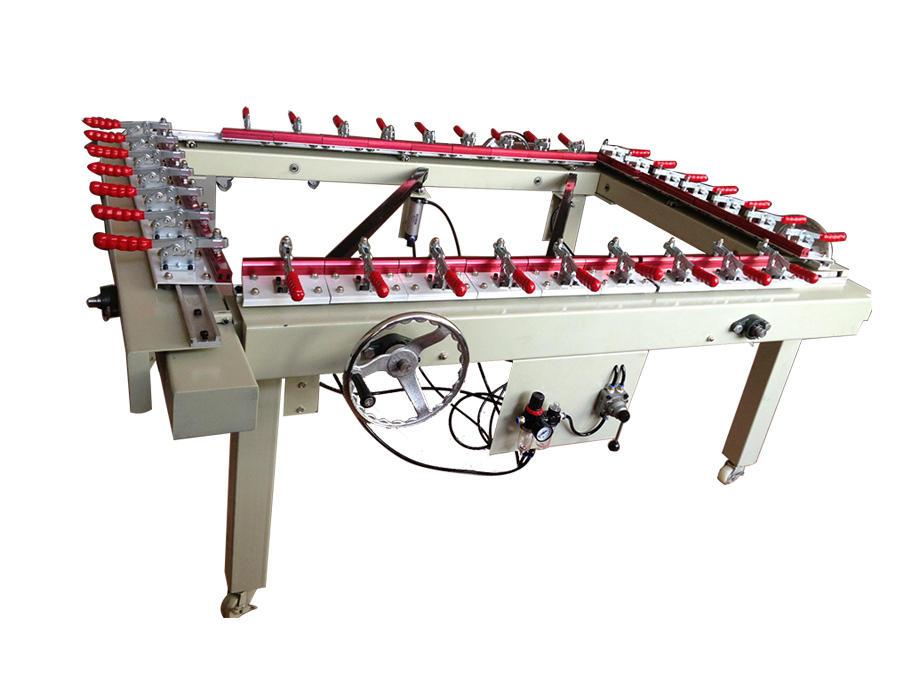

Modern screen stretcher systems incorporate pneumatic or hydraulic mechanisms that apply controlled, uniform pressure across multiple anchor points simultaneously. These sophisticated machines feature programmable tension settings, allowing operators to achieve precise specifications for different mesh types and frame sizes. The automation eliminates human variables that commonly affect manual stretching techniques, ensuring reproducible results across multiple screens.

Advanced screen stretching equipment includes features such as tension monitoring, automatic mesh alignment, and programmable stretching sequences. These capabilities enable consistent screen production while reducing operator skill requirements and minimizing physical strain. Professional-grade machines can stretch screens ranging from small graphics formats to large industrial sizes, accommodating diverse production requirements within a single investment.

Precision Control and Measurement

Professional screen stretching equipment integrates digital tension measurement systems that provide real-time feedback during the stretching process. These systems eliminate guesswork and ensure each screen meets exact specifications before adhesive application. The precision control prevents over-stretching, which can damage mesh threads, and under-stretching, which compromises print quality.

Digital controls allow operators to store specific settings for different mesh and frame combinations, creating a database of proven parameters that streamline future production. This systematic approach reduces setup time, minimizes material waste, and ensures consistent results regardless of operator experience level. The documentation capabilities support quality control procedures and help identify optimal settings for specific applications.

Frame Clamp Systems and Manual Methods

Traditional Clamping Approaches

Frame clamps represent the traditional approach to screen stretching, utilizing mechanical leverage to apply tension through manual force application. These systems typically consist of adjustable clamps that grip the mesh edges while operators apply tension through various mechanisms such as threaded rods, cam levers, or pneumatic cylinders. The manual nature of these systems requires significant operator skill and experience to achieve consistent results.

While frame clamps offer lower initial investment costs, they demand considerable physical effort and time investment for each screen. The sequential nature of manual stretching means operators must work methodically around the frame perimeter, adjusting tension incrementally to achieve uniform results. This process becomes increasingly challenging with larger frame sizes and higher mesh counts that require greater tension levels.

Skill Requirements and Learning Curves

Successful frame clamp operation requires operators to develop sophisticated tactile skills for tension assessment and adjustment. Experienced operators learn to recognize proper tension through visual inspection and physical testing, but this expertise develops slowly through extensive practice. The learning curve creates consistency challenges in production environments where multiple operators may work on screen preparation.

Training new operators on frame clamp systems involves considerable time investment and mentorship from experienced personnel. The manual nature of the process means that operator fatigue can affect quality consistency throughout production shifts. Physical strain associated with repetitive stretching motions may also create ergonomic concerns in high-volume production environments.

Comparative Analysis of Performance Factors

Speed and Efficiency Considerations

Production speed represents a critical factor when comparing screen stretching methods, particularly in commercial environments where screen preparation time directly impacts profitability. Automated screen stretching equipment typically completes the tensioning process in minutes, while manual frame clamp methods may require thirty minutes or more per screen depending on size and complexity.

The efficiency advantage extends beyond individual screen preparation time to include setup consistency and reduced rework requirements. Automated systems eliminate the trial-and-error approach common with manual methods, reducing material waste and operator time investment. The time savings compound significantly in high-volume production environments where dozens of screens require preparation daily.

Quality Consistency and Reproducibility

Consistency represents perhaps the most significant differentiator between automated and manual screen stretching approaches. Professional screen stretching equipment delivers identical results across multiple screens through precise mechanical control and digital monitoring systems. This consistency ensures predictable print behavior and reduces variables that can affect production quality.

Manual frame clamp systems introduce human variables that affect consistency even with experienced operators. Factors such as operator fatigue, technique variations, and subjective tension assessment create unavoidable inconsistencies that may impact print quality. The cumulative effect of these variations becomes more pronounced in demanding applications where tight tolerances are essential for acceptable results.

Cost Analysis and Return on Investment

Initial Investment Considerations

The initial cost difference between frame clamps and professional screen stretching equipment represents a significant decision factor for many screen printing operations. Basic frame clamp systems may cost hundreds of dollars, while professional automated equipment requires investments of several thousand to tens of thousands of dollars depending on capabilities and size requirements.

However, the initial cost comparison alone provides an incomplete picture of the total investment required. Frame clamp systems require significant labor investment for each screen, while automated equipment reduces labor requirements and increases production capacity. The labor cost difference often justifies the higher equipment investment within months of installation in commercial production environments.

Long-term Operational Costs

Long-term operational costs include factors beyond initial equipment purchase prices, encompassing labor costs, material waste, screen replacement frequency, and production capacity limitations. Automated screen stretching equipment typically reduces all these cost factors through improved efficiency and consistency compared to manual methods.

Screen replacement costs represent a significant ongoing expense that automated stretching equipment can substantially reduce through precise tension control and consistent application. Screens stretched with professional equipment typically last longer and perform more consistently throughout their service life. The reduced replacement frequency and improved performance characteristics often justify the higher initial investment through reduced ongoing operational costs.

Applications and Industry Considerations

Small-Scale and Hobby Applications

Small-scale screen printing operations and hobby applications may find frame clamps adequate for limited production requirements where speed and absolute consistency are less critical factors. These applications often prioritize lower initial investment over production efficiency and may accept longer preparation times in exchange for reduced equipment costs.

However, even small-scale operations benefit from the consistency and ease of use provided by automated screen stretching equipment. The reduced skill requirements and improved results may justify the investment for operations planning to grow or seeking to improve their print quality standards. The decision often depends on production volume expectations and quality requirements for specific applications.

Commercial and Industrial Requirements

Commercial screen printing operations typically require the speed, consistency, and capacity provided by professional screen stretching equipment. The demanding production schedules and quality standards common in commercial environments make manual stretching methods impractical for sustained operations. The investment in automated equipment becomes essential for maintaining competitive production capabilities.

Industrial applications with strict quality requirements and high-volume production demands virtually require automated screen stretching capabilities. The precision control and documentation features of professional equipment support quality control procedures and ensure consistent results across large production runs. These applications justify the equipment investment through improved efficiency and reduced quality-related costs.

FAQ

What tension levels should I target for different mesh counts

Tension requirements vary significantly based on mesh count, thread diameter, and application requirements. Fine mesh counts typically require 15-25 Newtons per centimeter, while coarser meshes may need 25-35 Newtons per centimeter. Consult mesh manufacturer specifications and conduct test prints to determine optimal tension levels for specific applications. Professional screen stretching equipment allows precise adjustment to meet these varying requirements consistently.

How long do properly stretched screens typically last

Screen lifespan depends on multiple factors including initial tension quality, mesh type, ink chemistry, and usage patterns. Screens stretched with professional equipment and proper technique typically last 500-2000 impressions for standard applications. Industrial applications with aggressive inks or substrates may reduce lifespan, while careful handling and maintenance can extend screen life significantly beyond typical expectations.

Can I convert from frame clamps to automated stretching gradually

Many operations successfully transition from manual to automated screen stretching by starting with a smaller automated unit and gradually expanding capacity. This approach allows operators to gain experience with automated systems while maintaining production capability during the transition period. The improved consistency and efficiency typically justify expanding automated capabilities as production requirements grow.

What maintenance requirements apply to screen stretching equipment

Automated screen stretching equipment requires regular maintenance including lubrication of moving parts, calibration of tension measurement systems, and replacement of wear components such as clamps and seals. Most professional equipment includes maintenance scheduling systems and diagnostic capabilities that simplify routine care. Proper maintenance ensures consistent performance and extends equipment lifespan significantly compared to neglected systems.