The screen printing industry continues to evolve with advanced technology and precision equipment, making the selection of the right screen stretcher more critical than ever in 2025. Professional screen printers, whether operating small studios or large commercial facilities, understand that achieving consistent tension and perfect mesh alignment directly impacts print quality and production efficiency. A high-quality screen stretcher serves as the foundation of successful screen printing operations, ensuring that every frame meets the exacting standards required for professional output. The investment in premium stretching equipment pays dividends through reduced waste, improved registration accuracy, and enhanced overall print quality that clients demand.

Essential Features of Modern Screen Stretching Equipment

Precision Tensioning Mechanisms

Modern screen stretching equipment incorporates sophisticated tensioning systems that provide consistent and repeatable results across multiple frame sizes. The most advanced models feature digital tension meters that display real-time measurements, allowing operators to achieve precise tension specifications for different mesh types and thread counts. Pneumatic stretching systems offer superior control compared to manual alternatives, providing smooth and gradual tension application that prevents mesh damage. These precision mechanisms ensure that every screen achieves optimal tension levels, typically ranging from 15 to 25 Newtons per centimeter depending on the mesh specification and intended application.

The integration of servo-controlled stretching arms represents the latest advancement in precision tensioning technology. These systems can store multiple tension profiles for different mesh types, automatically adjusting parameters based on the selected program. This level of automation reduces operator error and ensures consistent results regardless of skill level or experience. Professional facilities utilizing these advanced systems report significant improvements in screen consistency and reduced setup times between different jobs.

Frame Compatibility and Versatility

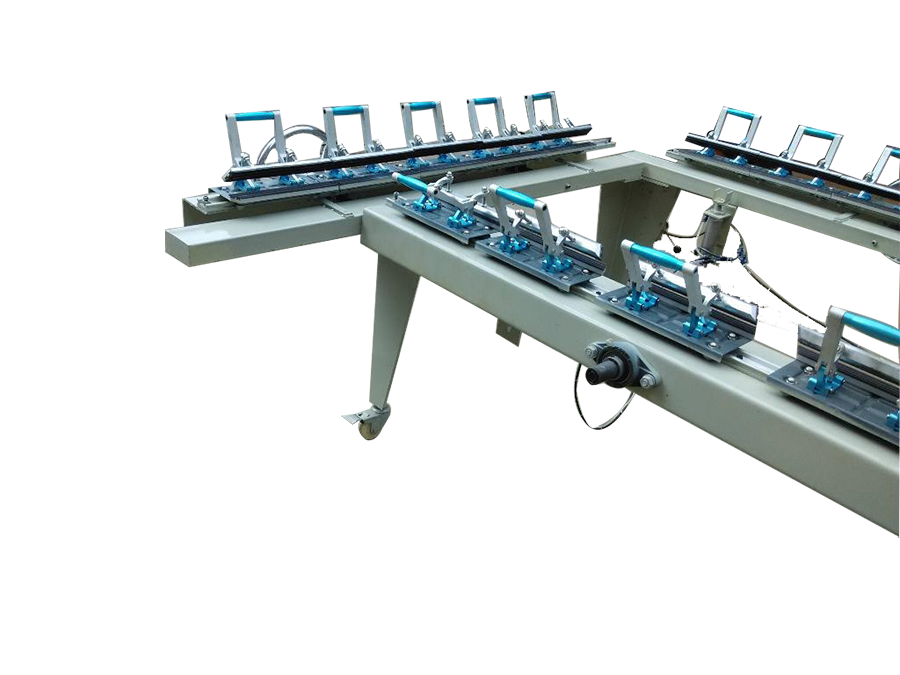

Leading screen stretching equipment accommodates a wide range of frame sizes and configurations, from small format frames measuring 8x10 inches to large industrial frames exceeding 40x60 inches. Modular clamping systems allow operators to quickly reconfigure the stretcher for different frame dimensions without extensive setup procedures. Universal frame adapters ensure compatibility with both aluminum and wooden frame types, providing flexibility for facilities that work with diverse client requirements. The ability to handle various frame thicknesses and profiles makes these machines valuable investments for growing businesses.

Advanced models feature quick-change frame holders that significantly reduce setup time between different frame sizes. These systems often incorporate color-coded positioning guides and digital readouts that display frame dimensions and recommended settings. The versatility extends to mesh compatibility, with top-tier equipment handling everything from coarse mesh used for textile printing to ultra-fine mesh required for electronics and precision applications.

Top Commercial Screen Stretching Solutions

Pneumatic Screen Stretching Systems

Pneumatic screen stretching systems represent the gold standard for commercial screen printing operations, offering unparalleled precision and consistency in mesh tensioning. These systems utilize compressed air to power stretching mechanisms, providing smooth and controlled tension application that prevents sudden jerking or uneven stress distribution. The pneumatic approach allows for precise pressure regulation through digital controls, enabling operators to achieve exact tension specifications for different mesh types and applications. Most commercial facilities prefer pneumatic systems due to their reliability, ease of operation, and ability to maintain consistent tension across large production runs.

The latest pneumatic models incorporate advanced feedback systems that monitor tension in real-time and automatically adjust pressure to maintain optimal levels throughout the stretching process. These systems often feature multiple pressure zones, allowing for differential tensioning that compensates for frame irregularities or mesh variations. Professional users report that pneumatic systems reduce mesh waste by up to 30% compared to manual stretching methods, while also improving overall screen quality and longevity.

Hydraulic Screen Stretching Equipment

Hydraulic screen stretching equipment offers exceptional power and precision for demanding applications requiring high tension levels or working with challenging mesh materials. These systems utilize hydraulic cylinders to provide consistent and powerful stretching force, making them ideal for large format screens and heavy-duty mesh applications. The hydraulic approach excels in applications where maximum tension levels are required, such as industrial screen printing or specialized technical applications. The smooth operation of hydraulic systems ensures even tension distribution across the entire mesh surface, preventing localized stress concentrations that can lead to premature failure.

Modern hydraulic stretching equipment incorporates proportional valve controls that provide infinite adjustment of stretching force and speed. This level of control allows operators to develop custom stretching profiles for different mesh types and frame configurations. The robust construction of hydraulic systems makes them suitable for continuous operation in high-volume production environments, where reliability and consistent performance are paramount considerations.

Manual vs Automated Screen Stretching Methods

Traditional Manual Stretching Techniques

Manual screen stretching remains relevant for small studios, specialty applications, and situations where budget constraints limit equipment options. Traditional manual methods rely on operator skill and experience to achieve proper tension levels, using simple tools such as stretching pliers and tension meters. While manual stretching requires more time and physical effort, experienced operators can achieve excellent results with proper technique and quality tools. The manual approach offers maximum flexibility for unusual frame sizes or specialized applications that may not be compatible with automated equipment.

The key to successful manual stretching lies in understanding mesh behavior and developing consistent techniques for tension application. Experienced operators learn to recognize the visual and tactile cues that indicate proper tension levels, though this skill requires significant practice to develop. Manual stretching also allows for immediate adjustments and corrections during the process, providing a level of hands-on control that some artisans prefer for specialty work or prototype development.

Benefits of Automated Stretching Systems

Automated screen stretching systems deliver consistent results regardless of operator skill level, making them invaluable for facilities with multiple operators or high turnover rates. These systems eliminate human error in tension measurement and application, ensuring that every screen meets exact specifications. The repeatability of automated systems is particularly important for large production runs where screen-to-screen consistency directly impacts final product quality. Time savings represent another significant advantage, with automated systems typically completing the stretching process 3-5 times faster than manual methods.

The data logging capabilities of modern automated systems provide valuable production insights and quality control documentation. These systems can track tension levels, stretching times, and other parameters for each screen, creating a permanent record that supports quality assurance programs. Advanced models can even detect mesh defects or irregularities during the stretching process, alerting operators to potential issues before they impact production quality.

Industry-Specific Screen Stretching Requirements

Textile Screen Printing Applications

Textile screen printing applications typically require moderate tension levels that balance print quality with mesh durability for long production runs. The screen stretcher used in textile applications must accommodate the frequent mesh changes required for different ink types and fabric substrates. Textile printers often work with larger screen sizes to maximize production efficiency, requiring stretching equipment capable of handling frames up to 60 inches or larger. The tension requirements for textile applications usually range from 15-20 Newtons per centimeter, depending on the mesh count and fabric type being printed.

The durability requirements for textile screens are particularly demanding due to the abrasive nature of textile inks and the high impression counts typical of textile production. Screen stretching equipment for textile applications must provide consistent tension that maintains screen registration throughout extended print runs. Many textile facilities invest in multiple stretching stations to maintain continuous production while screens are being prepared or re-tensioned.

Electronics and Precision Printing

Electronics manufacturing and precision printing applications demand the highest levels of screen tension consistency and registration accuracy. These applications often utilize ultra-fine mesh counts exceeding 400 threads per inch, requiring specialized stretching techniques to prevent mesh damage during tensioning. The screen stretcher equipment used in precision applications must provide extremely stable and uniform tension distribution to achieve the tight registration tolerances required for multi-layer circuit boards and electronic components. Tension levels for precision applications typically range from 20-25 Newtons per centimeter or higher.

The cleanliness requirements for electronics applications also influence stretching equipment selection, with many facilities choosing systems that minimize contamination risks during screen preparation. Automated stretching systems are particularly valuable in precision applications because they eliminate variables introduced by manual handling and provide documented tension records required for quality certifications.

Screen Stretcher Maintenance and Optimization

Regular Maintenance Procedures

Proper maintenance of screen stretching equipment ensures consistent performance and extends equipment life while maintaining the precision required for professional screen printing operations. Daily maintenance routines should include cleaning all contact surfaces, checking pneumatic or hydraulic fluid levels, and verifying calibration of tension measurement systems. Weekly maintenance typically involves more thorough cleaning of all components, lubrication of moving parts according to manufacturer specifications, and inspection of wear components such as clamps and tensioning mechanisms. Monthly maintenance procedures often include recalibration of tension measurement systems and replacement of consumable components.

The importance of maintaining clean stretching equipment cannot be overstated, as contamination can transfer to mesh surfaces and affect subsequent printing quality. Regular cleaning with appropriate solvents removes ink residue, adhesive deposits, and other contaminants that can accumulate during normal operation. Proper lubrication of mechanical components prevents premature wear and ensures smooth operation of tensioning mechanisms.

Performance Optimization Strategies

Optimizing screen stretching equipment performance involves fine-tuning operational parameters to achieve the best possible results for specific applications and mesh types. Temperature control plays a crucial role in stretching consistency, as mesh materials exhibit different tensioning characteristics at various temperatures. Many facilities implement climate control systems to maintain stable temperatures in stretching areas, ensuring consistent results regardless of seasonal variations. Humidity control is equally important, as excessive moisture can affect mesh tension and adhesive performance.

Developing standardized stretching procedures for different mesh types and applications helps ensure consistent results across multiple operators and production shifts. These procedures should specify tension levels, stretching speeds, and dwell times for optimal mesh performance. Regular performance monitoring through tension measurements and print quality assessments provides feedback for continuous improvement of stretching procedures and equipment settings.

Cost Analysis and Return on Investment

Initial Equipment Investment

The initial investment in professional screen stretching equipment varies significantly based on automation level, size capacity, and precision requirements. Entry-level manual stretching systems suitable for small studios typically range from $2,000 to $8,000, while semi-automatic pneumatic systems for medium-sized operations range from $15,000 to $35,000. High-end automated stretching systems with advanced features and large format capabilities can cost $50,000 to $150,000 or more. The investment decision should consider not only initial cost but also long-term productivity gains, quality improvements, and labor savings.

Financing options are available from most equipment manufacturers, allowing facilities to spread the investment cost over several years while immediately benefiting from improved productivity and quality. Leasing arrangements can be particularly attractive for growing businesses that need to preserve capital for other investments while still accessing the latest stretching technology. The tax advantages of equipment purchases or leases can significantly reduce the effective cost of professional stretching equipment.

Productivity and Quality Benefits

Professional screen stretching equipment delivers measurable returns through improved productivity, reduced waste, and enhanced print quality that commands premium pricing. Automated stretching systems typically reduce screen preparation time by 60-80% compared to manual methods, allowing facilities to process more screens with the same labor resources. The consistency of professional stretching equipment reduces mesh waste by eliminating screens that fail to meet tension specifications, with many facilities reporting waste reductions of 25-40% after upgrading their stretching capabilities.

Quality improvements from professional stretching equipment enable facilities to accept more demanding work and charge premium rates for superior results. The improved registration accuracy and print consistency achieved with properly tensioned screens often justify rate increases of 15-25% for precision work. Customer satisfaction improvements from consistent quality also lead to increased repeat business and referrals, providing ongoing revenue benefits that continue long after the initial equipment investment.

FAQ

What tension level should I use for different mesh counts?

Mesh tension requirements vary based on thread count and application, with lower mesh counts typically requiring 15-18 Newtons per centimeter for textile printing and higher mesh counts needing 20-25 Newtons per centimeter for precision work. Fine mesh above 300 threads per inch often requires specialized tensioning techniques to prevent damage during stretching. The optimal tension also depends on the specific mesh material, with polyester and nylon meshes having different characteristics that affect tensioning requirements.

How often should screens be re-tensioned during production?

Screen tension naturally decreases during use due to mesh relaxation and printing stresses, typically requiring monitoring after every 500-1000 impressions for critical applications. Textile screens may maintain adequate tension for 2000-5000 impressions, while precision electronics screens may need attention after just 200-500 impressions. Regular tension monitoring with a calibrated meter helps determine the optimal re-tensioning schedule for specific applications and mesh types.

Can automated stretching systems handle all frame types and sizes?

Most modern automated stretching systems offer excellent versatility through adjustable clamping systems and modular frame holders, accommodating frame sizes from small format up to 40x60 inches or larger. However, unusual frame configurations or extremely large formats may require specialized equipment or custom modifications. It's important to verify frame compatibility with the equipment manufacturer before making a purchase decision, especially for facilities working with non-standard frame sizes.

What maintenance is required for hydraulic stretching systems?

Hydraulic stretching systems require regular fluid level checks, filter replacement every 6-12 months, and annual hydraulic system servicing to maintain optimal performance. Daily maintenance includes checking for fluid leaks and verifying proper operation of all controls and safety systems. The hydraulic fluid should be changed according to manufacturer recommendations, typically every 2-3 years or after a specified number of operating hours. Proper maintenance ensures reliable operation and prevents costly downtime from hydraulic system failures.